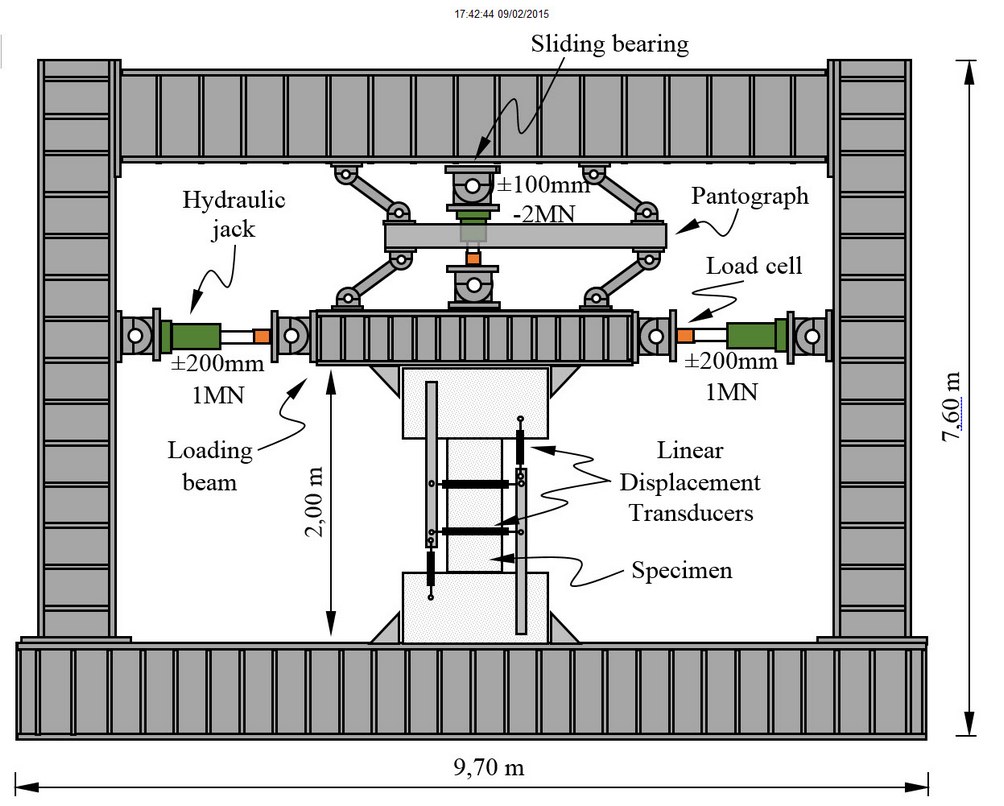

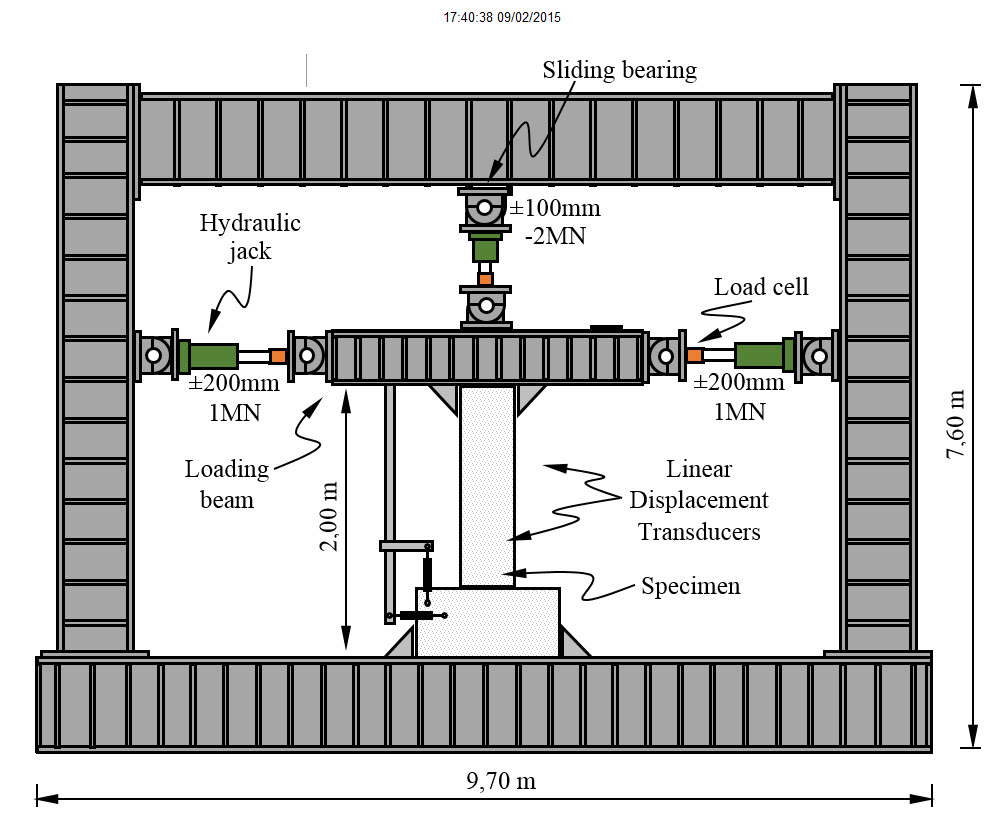

The structural testing equipment consists of a steel reaction frame with digitally controlled hydraulic loading system and digital data acquisition system.

Lateral load is applied using two identical hydraulic jacks with 200 mm maximum stroke and ±1MN loading capacity. Vertical load is applied using a hydraulic jack with 100mm maximum stroke, 2MN compression capacity and 1MN tension capacity. To restrict the rotation and the out of plane movement of the loading beam a pantograph is installed in between the reaction frame and the loading beam. Three load cells are used to measure the horizontal and vertical loads. Pairs of linear displacement transducers are installed to measure the horizontal and vertical displacements in between the top and bottom stubs.

The following load combinations are possible: bending with shear and bending with shear and axial load. The maximum weight of tested specimens is 7.0t and the maximum dimensions of the tested specimens are 2.50m by 3.00m.

The structural testing equipment was provided in 2004 by the Japanese International Cooperation Agency, within the Romanian-Japanese technical cooperation project for seismic risk reduction.

Test setup for a squat masonry or concrete wall with restricted rotations at both ends of the specimens. Maximum height of the specimen 2.45m (including the top and bottom stubs)

Test setup for a cantilever column, with restricted rotation at the bottom end and free rotation at the upper end. Maximum height of the specimen 2.45m (including the top and bottom stubs)